Effectively plan for manufacturing orders with demand forecasting in Business Central

One of the most crucial parts of managing a business is balancing supply and demand. Without proper balance, supply may be insufficient to meet demand causing a drop in customer satisfaction, or there may be too much supply thereby hurting profits. For manufacturers, Dynamics 365 Business Central includes robust planning functionality to give guidance on purchase and production orders to ensure items are in stock and available for customers.

Planning in Business Central

The planning features in Business Central utilize data for supply and demand to generate action items that will help balance supply to meet demand. This is driven primarily by examining predicted demand, actual demand, and inventory. Action items created by Business Central make suggestions to purchase new stock from vendors, set up production orders for manufacturing, or transfer inventory between locations. This feature will also take active orders into account and suggest alterations if more or fewer items are required.

For the planning feature to properly work, demand forecasts must be created.

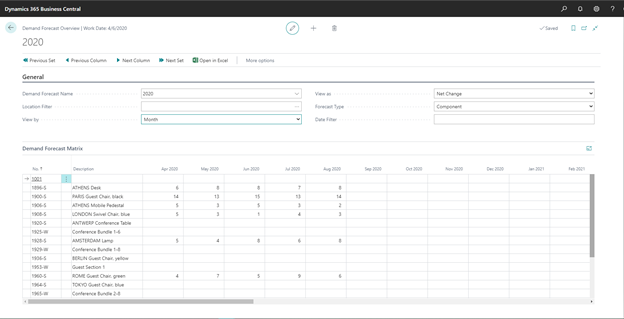

Demand forecasts are accessed via the aptly named Demand Forecasts page. For companies that will often make items to order rather than simply hold completed items to be shipped after sales, both sales and production forecasts are needed to accurately make predications.

Each forecast must be designated as one of three options: sales item, component, or both. Sales item types are used to forecast sales and production forecasting is accomplished through the component type. Both is used to give a read-only overview of both forecast types. The types can be quickly swapped in and out on the same screen.

Sales Order Planning and Order Planning pages, or in batches via the Planning Worksheet page. All supply-related orders, including production orders, have a Planning Flexibility field. This field indicates whether that particular order should be included in the system’s planning calculations for creating supply action items. Unlimited will include the order and None will set the order as static and keep it out of planning calculations.

There are a variety of planning functions. In order to run calculations of the master production schedule, navigate to the Planning Worksheets page. From this page, a Regenerative plan can be calculated which will completely reset the planning system by deleting all currently planned supply orders and recreating new orders. Calculating a Net Change plan will essentially update current planning with any new parameters that may have changed such as inventory or numbers on sales or production orders.

The Get Action Messages will give a notification of any changes made to the planning since the last time the plan was generated. When selecting Calculate Regenerative Plan or Calculate Net Change Plan, a window will appear in which the data for the plan can be defined. Demand forecasts can be indicated for inclusion in the calculation here as well. After running, the planning worksheet will be filled with the planning lines.

Get started

The manufacturing and planning capabilities of Dynamics 365 Business Central will empower manufacturers of all sizes to take better control of their manufacturing and supply management. Learn more about how these two features and the rest of Business Central can help your business by clicking the button below to connect with our Business Central Manufacturing team!